Case

News

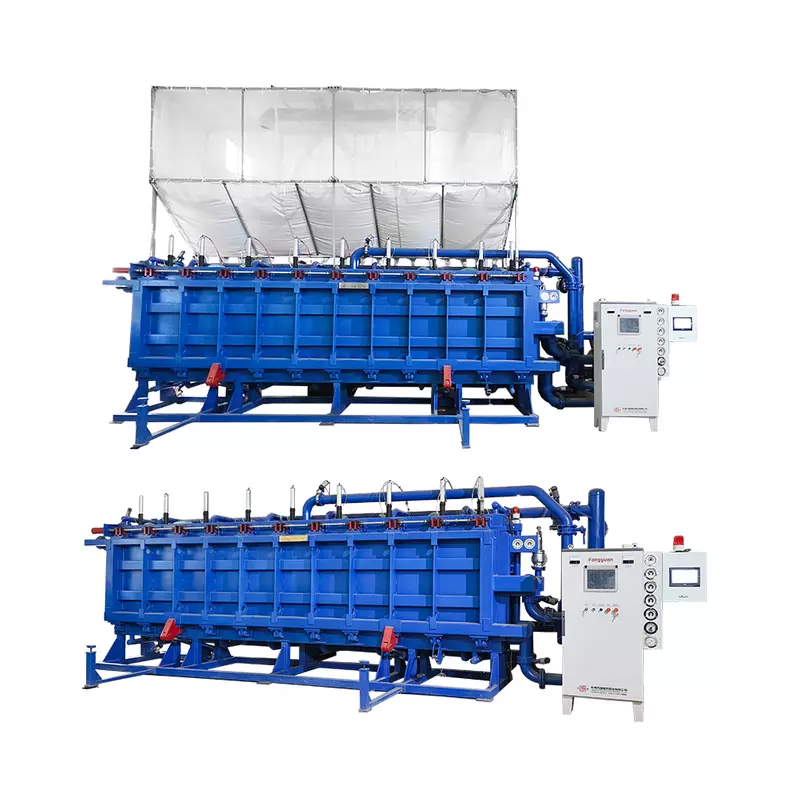

- Advanced EPS Machine for Polystyrene Box Molding

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

Contact Us

Mobile: +86-15010314731

Phone: +86-15010314731

Email: [email protected]

Address: EPP Machine:EPP plastic machine, EPP foam machine,EPP Shuttle Moulding Machine

EPS Machine Operating Process The core operation of the EPS machine involves introducing raw material into the system. The material is foamed by steam or electric heating, after which it is fed into the plastic molding machine. Once molded, the product may be cut or dried. From here, the EPS machine directs the finished products to cutting machines or drying systems to complete the process.

EPP Machine Operating Process The process of manufacturing with an EPP machine begins with feeding raw polypropylene material into the machine. The material is then expanded through a controlled heating process, which softens the polymer and allows it to be molded into the desired shape. The EPP machine ensures precise temperature control and uniform expansion, resulting in high-quality, lightweight products that maintain excellent structural integrity.

Dual Functionality of ETPU Machine One of the standout features of the ETPU machine from Fangyuan is its dual functionality. In addition to producing ETPU foam products, the ETPU machine can also operate as an EPP molding machine. This multi-purpose capability makes the ETPU machine an excellent investment for manufacturers looking to diversify their production without needing separate equipment for ETPU and EPP processes.

EPS Machine for High-Efficiency Moulding: Fangyuan’s Premium Solution

Fangyuan’s EPS Foam Shape Moulding Machine brings high efficiency and versatility to EPS foam production. This EPS machine includes an insulated mould cavity to save steam and energy, ideal for manufacturers focused on cost-effective production.

The vertical dual-material barrel enables dual-density production, enhancing productivity. Precise steam heating control maintains product quality, and the energy recovery system ensures sustainable operation. Trusted in the industry, Fangyuan’s EPS machine is reliable for diverse product specifications.

8. Sustainable EPS Foam Production with Fangyuan’s EPS Machine

The EPS Foam Shape Moulding Machine by Fangyuan combines efficiency with sustainability. Designed with an insulated mould cavity, this EPS machine reduces steam consumption, lowering operational costs. It supports dual-density production, accommodating a variety of EPS products, from packaging to insulation.

The energy recovery system minimizes vacuum power use, promoting an eco-friendly manufacturing process. Backed by Fangyuan’s quality assurance, this EPS machine is ideal for businesses focused on reliable, cost-effective production.

9. High-Performance EPS Machine for Expanded Polystyrene Moulding

Fangyuan’s EPS Foam Shape Moulding Machine is built to deliver high-performance results for EPS manufacturers. With a dual-density production feature, this EPS machine offers flexibility, allowing for various product designs. The built-in insulation system reduces steam usage, cutting down energy expenses.

Its precise steam heating control guarantees a smooth moulding process, and the energy recovery system ensures efficient vacuum use. This EPS machine is a dependable option for businesses needing consistent, high-quality foam production.

Case

-

EPS Underfloor Heating Panel Forming Machine

-

SPJ-75 EPP Expandable Polypropylene Pre-expander foaming Machine

-

Fangyuan eps foam board block making machine

-

E-TPU Shoes Soles Shape Molding Machine

-

1018Z Series Rotation ETPU EPP EPS Shape Molding Machine

-

EPP Shuttle Moulding Machine for Car Seat

-

Automatic Light Weight EPS Foam Plate Sheet Block Moulding Making Machine

-

EPS Foam Fruit Box Moulding Machine

Customer Service QQ

Customer Service QQ