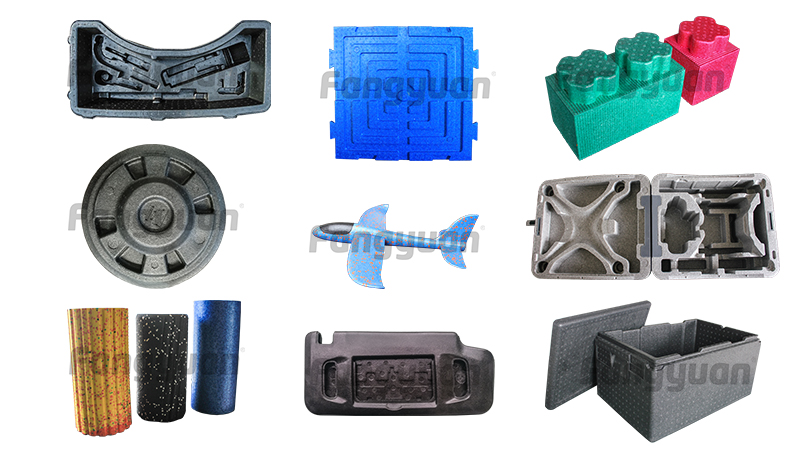

Case

News

- Advanced EPS Machine for Polystyrene Box Molding

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

Contact Us

Mobile: +86-15010314731

Phone: +86-15010314731

Email: [email protected]

Address: EPP Machine:EPP plastic machine, EPP foam machine,EPP Shuttle Moulding Machine

EPS Machine Operating Process The core operation of the EPS machine involves introducing raw material into the system. The material is foamed by steam or electric heating, after which it is fed into the plastic molding machine. Once molded, the product may be cut or dried. From here, the EPS machine directs the finished products to cutting machines or drying systems to complete the process.

EPP Machine Operating Process The process of manufacturing with an EPP machine begins with feeding raw polypropylene material into the machine. The material is then expanded through a controlled heating process, which softens the polymer and allows it to be molded into the desired shape. The EPP machine ensures precise temperature control and uniform expansion, resulting in high-quality, lightweight products that maintain excellent structural integrity.

Dual Functionality of ETPU Machine One of the standout features of the ETPU machine from Fangyuan is its dual functionality. In addition to producing ETPU foam products, the ETPU machine can also operate as an EPP molding machine. This multi-purpose capability makes the ETPU machine an excellent investment for manufacturers looking to diversify their production without needing separate equipment for ETPU and EPP processes.

EPP Machine-c

SPJ-75 EPP Expandable Polypropylene Pre-expander foaming Machine

SPJ-75 EPP Expandable Polypropylene Pre-expander foaming Machine

SPJ-75 EPP Expandable Polypropylene Pre-expander foaming Machine

EPP Expandable Polypropylene Pre-expander foaming Machine

Main Features:

1. Accurate weighing and quantitative feeding system replaces time control feeding, and the level sensor ends heating to eliminate external instability factors and ensure accurate pre-acquisition weight.

2. Relief valve and proportional valve PID control barrel pressure, with compressed air bypass, achieving the best foaming pressure and minimum steam consumption.

3. The bottom is wedge-shaped and permeable, with large intake area and uniform steam distribution.

4. Hot air discharging by fan, realizing fast discharging and less machine condensation water.

5. Electrical appliances, pneumatic components, valves, etc. are all well-known brands at home and abroad to ensure the stability and reliability of this pre-expander foaming machine operation, and prolong the service life.

6. Automatic density measuring devices are optional.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

- Previous Article: EPP Shuttle Moulding Machine for Car Seat

- Next Article: 没有了!

Customer Service QQ

Customer Service QQ