Case

News

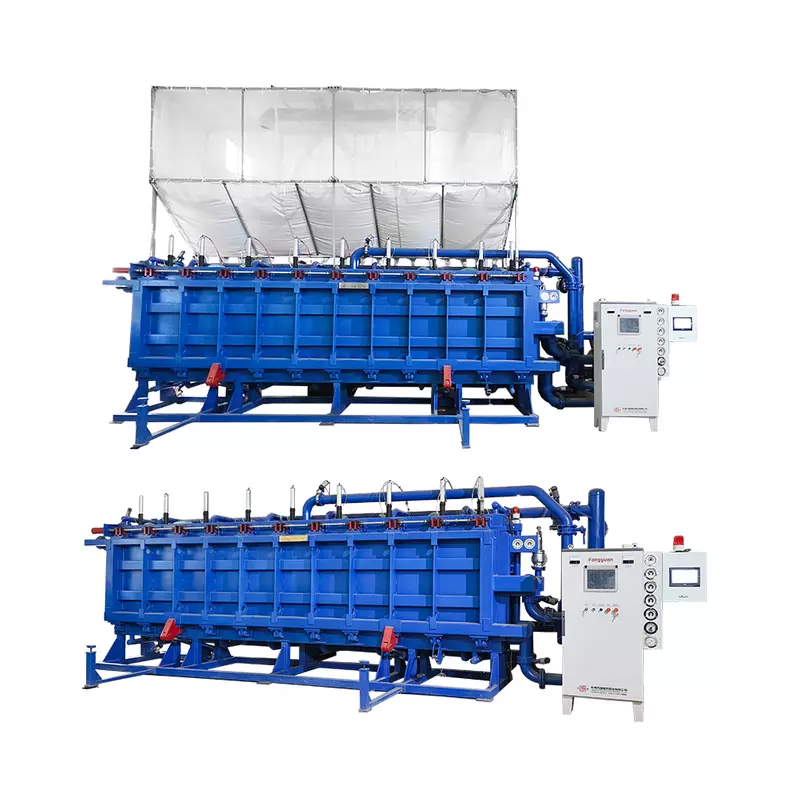

- Advanced EPS Machine for Polystyrene Box Molding

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

Contact Us

Mobile: +86-15010314731

Phone: +86-15010314731

Email: [email protected]

Address: EPP Machine:EPP plastic machine, EPP foam machine,EPP Shuttle Moulding Machine

EPS Machine Operating Process The core operation of the EPS machine involves introducing raw material into the system. The material is foamed by steam or electric heating, after which it is fed into the plastic molding machine. Once molded, the product may be cut or dried. From here, the EPS machine directs the finished products to cutting machines or drying systems to complete the process.

EPP Machine Operating Process The process of manufacturing with an EPP machine begins with feeding raw polypropylene material into the machine. The material is then expanded through a controlled heating process, which softens the polymer and allows it to be molded into the desired shape. The EPP machine ensures precise temperature control and uniform expansion, resulting in high-quality, lightweight products that maintain excellent structural integrity.

Dual Functionality of ETPU Machine One of the standout features of the ETPU machine from Fangyuan is its dual functionality. In addition to producing ETPU foam products, the ETPU machine can also operate as an EPP molding machine. This multi-purpose capability makes the ETPU machine an excellent investment for manufacturers looking to diversify their production without needing separate equipment for ETPU and EPP processes.

EPS Machine-c

EPS Underfloor Heating Panel Forming Machine

Built to handle a variety of product sizes, the EPS Machine offers flexibility with templates ranging from 1400×1200 mm to 1800×1600 mm. This adaptability, combined with its two-step hydraulic system and compressed feeding system, makes it a versatile tool for foam block manufacturers. The central energy system further enhances production control, ensuring smooth operations.

The EPS Machine incorporates a Liquid Ring Vacuum pump and condenser in its vacuum system, which accelerates the injection process and eliminates the need for additional drying steps. This vacuum technology not only speeds up production but also ensures easy mold ejection, reducing energy consumption and improving efficiency.

Maintaining the right energy pressure is essential for producing high-quality foam blocks. The EPS Machine includes a relief damper that adjusts during mold release and heating, while the compressed air filling system optimizes energy usage. This design minimizes production time and ensures that the final product remains free from deformation or surface defects.

A standout feature of this EPS Machine is its custom central energy system, which manages all steam and air needs during production. This system ensures even air distribution and is easily adjustable, making it a key element in the machine’s high-efficiency, low-energy foam block production process.

- Previous Article: Fangyuan eps foam board block making machine

- Next Article: 没有了!

Customer Service QQ

Customer Service QQ