News

News

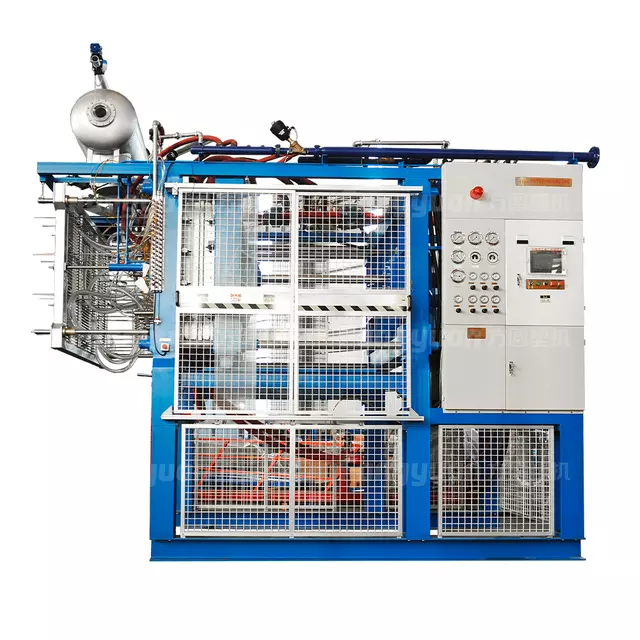

- Advanced EPS Machine for Polystyrene Box Molding

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

- EPS Polystyrene Vegetables Package Box Shape Molding Machine

Contact Us

Mobile: +86-15010314731

Phone: +86-15010314731

Email: [email protected]

Address: EPP Machine:EPP plastic machine, EPP foam machine,EPP Shuttle Moulding Machine

gongsi-New

Molding System for EPS Underfloor Heating Insulation Panels

- Author: epp-machine.com

- Publication Date: 2024-10-25

- Views: 139

The EPS Machine is designed to accommodate a range of product sizes, with templates ranging from 1400×1200 mm to 1800×1600 mm. Featuring a two-step hydraulic system and compressed feeding mechanism, this machine ensures precise and efficient foam block production. Its central energy system is designed to optimize performance and resource use.

The vacuum system, equipped with a Liquid Ring Vacuum pump and condenser, accelerates the injection process while eliminating the need for extra drying steps. This system also improves mold ejection efficiency, reducing energy consumption and boosting productivity.

Effective energy pressure management is vital for maintaining product quality. The EPS Machine includes a relief damper that regulates steam during molding, while compressed air helps minimize energy use. This ensures that foam blocks are produced without deformation or surface defects.

The EPS Machine comes with a custom central energy system that controls steam and air intake. Designed with enlarged pipes and valves, this system ensures even air distribution, making it easier to adjust production settings and maintain optimal working conditions.

- Previous Article: Production Machine for EPS Underfloor Heating Panels

- Next Article: EPS Underfloor Heating Insulation Panel Maker Machine

Customer Service QQ

Customer Service QQ