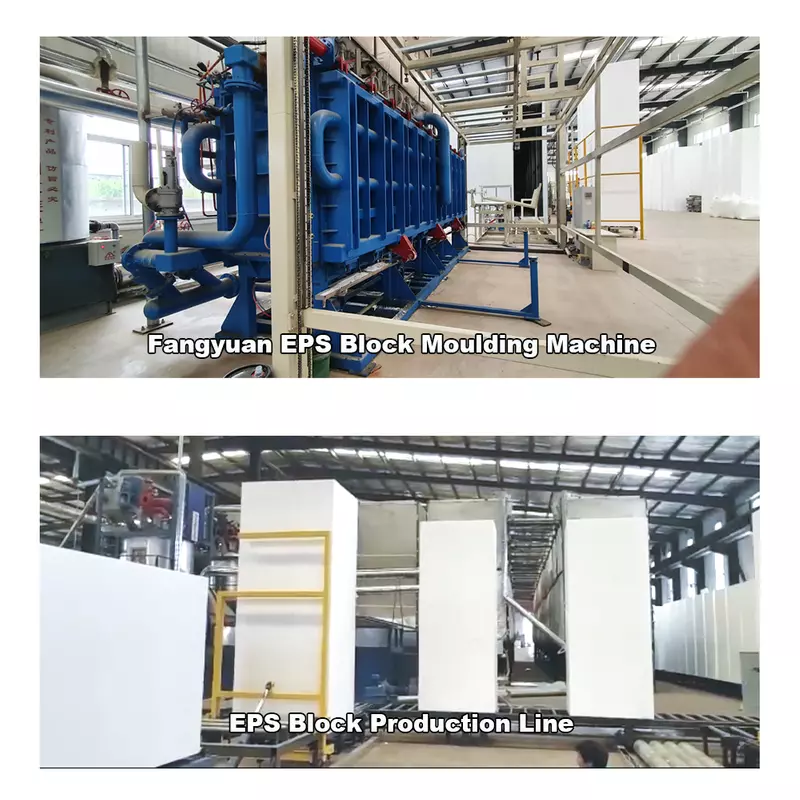

The EPS Machine is designed to handle varying product sizes, with templates ranging from 1400×1200 mm to 1800×1600 mm. Its two-step hydraulic system, along with the compressed feeding system, ensures precise control and high production efficiency. The central energy system streamlines the entire process, ensuring consistent performance.

The vacuum system in this EPS Machine features a Liquid Ring Vacuum pump and condenser, which speeds up the injection process and removes the need for extra drying. The vacuum-assisted mold ejection is smooth and energy-efficient, resulting in lower energy consumption and higher productivity.

Maintaining the proper energy pressure is essential for quality control. The EPS Machine uses a relief damper to manage steam release during the molding process, while the compressed air filling system helps reduce energy usage and improve product quality. This system ensures that foam blocks remain free from deformation and surface imperfections.

The central energy system of the EPS Machine is tailored to control all air and steam needs during production. This system is equipped with enlarged pipes and valves for consistent air distribution, making it easy to adjust production parameters and achieve the best working conditions.

Product Description 5

The EPS Machine offers flexibility in production with templates that support various product sizes, from 1400×1200 mm to 1800×1600 mm. This adaptability, combined with the machine's two-step hydraulic and compressed feeding systems, ensures optimal control and efficiency throughout the manufacturing process. The integrated central energy system enhances overall performance.

Equipped with a Liquid Ring Vacuum pump and condenser, the EPS Machine features a vacuum system that improves vacuity and accelerates the injection process. This eliminates the need for extra drying steps, allowing for easy mold ejection and reducing energy consumption, making it an efficient option for foam block production.

Energy pressure control is critical for achieving consistent results. The EPS Machine includes a relief damper that regulates steam release during molding, while compressed air ensures efficient filling. This design reduces energy consumption while maintaining product quality, ensuring blocks are free from deformation or surface imperfections.

The machine's custom-designed central energy system controls all steam and air intake during production. With enlarged pipes and valves, this system ensures even air distribution and easier adjustments, making the EPS Machine a reliable and efficient choice for manufacturers.

Product Description 6

The EPS Machine is built to handle multiple product sizes, with templates ranging from 1400×1200 mm to 1800×1600 mm. This range of flexibility, along with the machine’s two-step hydraulic system and compressed feeding system, allows for precise and efficient foam block production. The central energy system optimizes the use of resources, ensuring consistent performance.

The machine’s vacuum system, featuring a Liquid Ring Vacuum pump and condenser, enhances the injection process, speeding it up while removing the need for additional drying. This system also simplifies mold ejection, reducing energy consumption and increasing overall production efficiency.

Precise energy pressure control is key to producing high-quality foam blocks. The EPS Machine uses a relief damper to release steam during the molding process, and compressed air ensures efficient filling. This system optimizes energy usage while ensuring that the final product remains free from defects.

The central energy system, designed specifically for the EPS Machine, controls steam and air intake during production. Its enlarged pipes and valves ensure smooth operation, making it easy to adjust production settings and maintain efficient working conditions.

Product Description 7

The EPS Machine is designed to accommodate a range of product sizes, with templates ranging from 1400×1200 mm to 1800×1600 mm. Featuring a two-step hydraulic system and compressed feeding mechanism, this machine ensures precise and efficient foam block production. Its central energy system is designed to optimize performance and resource use.

The vacuum system, equipped with a Liquid Ring Vacuum pump and condenser, accelerates the injection process while eliminating the need for extra drying steps. This system also improves mold ejection efficiency, reducing energy consumption and boosting productivity.

Effective energy pressure management is vital for maintaining product quality. The EPS Machine includes a relief damper that regulates steam during molding, while compressed air helps minimize energy use. This ensures that foam blocks are produced without deformation or surface defects.

The EPS Machine comes with a custom central energy system that controls steam and air intake. Designed with enlarged pipes and valves, this system ensures even air distribution, making it easier to adjust production settings and maintain optimal working conditions.

Product Description 8

The EPS Machine is equipped with flexible template options ranging from 1400×1200 mm to 1800×1600 mm, making it adaptable for a variety of production needs. Its two-step hydraulic system and compressed feeding mechanism ensure precise, high-quality foam block production. The machine’s central energy system ensures that every stage of the process runs efficiently.

This EPS Machine features an advanced vacuum system with a Liquid Ring Vacuum pump and condenser, allowing for faster injection cycles without requiring additional drying. The vacuum system also aids in the smooth ejection of molds, saving energy and improving overall production efficiency.

Precise control over energy pressure is essential for consistent product quality. The EPS Machine includes a relief damper for steam regulation and a compressed air system that optimizes energy consumption. This setup ensures that the final product is defect-free and maintains its shape.

A custom-designed central energy system regulates all steam and air inputs for the EPS Machine, featuring enlarged pipes and valves for easy adjustment and consistent air distribution, ensuring a smooth and efficient production process.

Product Description 9

Designed for versatility, the EPS Machine offers a range of template sizes from 1400×1200 mm to 1800×1600 mm, accommodating various production needs. The machine’s two-step hydraulic system and compressed feeding mechanism provide precise control, ensuring efficient foam block manufacturing. The central energy system guarantees smooth operation throughout the process.

The EPS Machine includes a state-of-the-art vacuum system with a Liquid Ring Vacuum pump and condenser, which speeds up the injection process and eliminates the need for additional drying. The vacuum system also facilitates easy mold ejection, reducing energy consumption and enhancing productivity.

Energy pressure regulation is vital for

Customer Service QQ

Customer Service QQ